X-Ray Inspection & Analysis

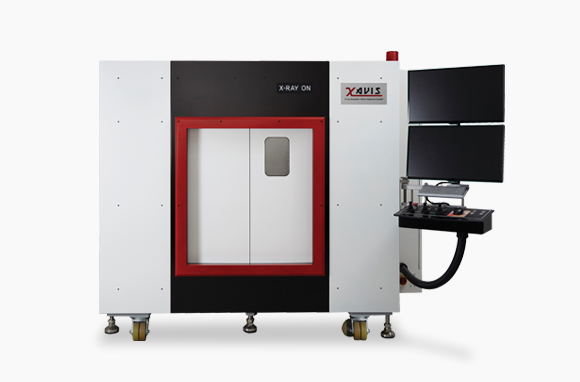

X-Ray for Electronics

Designed for the electronics industry, we offer advanced X-ray inspection systems that provide high-resolution imaging for detailed analysis of electronic components and assemblies. These systems are particularly effective in inspecting solder joints, PCB (printed circuit board) integrity, and detecting hidden defects or failures that are not visible through traditional inspection methods. Systems are available with automatic void detection and CT rendering.

X-Ray for Battery Technology

These systems offer precise, non-destructive imaging that can detect internal defects, structural issues, and inconsistencies within battery cells, modules, and packs. Using advanced X-ray technology, Xavis systems can inspect critical components like electrodes, separators, and internal wiring to ensure proper assembly and performance. Systems are available for manual or in-line processing improving battery quality, reliability, and safety in the growing energy storage and electric vehicle sectors.

X-Ray For Semiconductor

These systems enable detailed imaging to detect defects such as cracks, voids, delaminations, and wire bonding issues within microchips, wafers, and packaged devices. The advanced X-ray technology used in Xavis systems ensures precise analysis of complex structures at the microscopic level, allowing for early identification of manufacturing flaws that could impact the performance or reliability of semiconductor products. Open or closed tube systems are available depending on your specific resolution requirements.

X-Ray For Large Area Applications

We offer large area, high-resolution imaging for the inspection of large or complex components in industries such as aerospace, automotive, and construction. These systems are capable of scanning larger objects, such as structural components, panels, or assemblies, to detect internal defects like cracks, voids, or structural inconsistencies. Xavis systems offer higher KV, CT scanning and rendering with a 4-axis travel, and a scanning range up to 500mm